Self-healing Concrete and Enzyme-Based Construction Materials

Scientists at Enzymatic have developed and secured patents for a revolutionary technology that helps concrete last longer, prevent corrosion, and do it at a significantly lower dosage.

About Enzymatic

We combine the world’s most consumed man-made material with the world’s fastest known enzymes to produce environmentally-friendly products for the construction industry.

For The First Time in History, More

Infrastructure Will Be Good For

The Environment

EC3

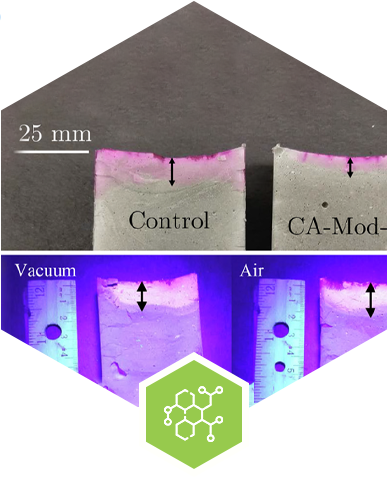

EC3 is a low dose permeability reducer. Other crystalline additives require up to 40 lbs of product per cubic yard of concrete and does not absorb atmospheric CO2. Using our technology, you only need an amount equivalent to a couple of drops of water and our catalyst will create the crystalline additive in your concrete in real time, simply add a little bit of powder to the water used to mix your concrete.

Enzymatic Concrete

Recycling (ECR)

When people say "Concrete Recycling" today, they mean large chunks of concrete crushed into small pieces. The problem with this process is that old cement is still stuck to the "recycled" concrete and it can't bond with new cement, resulting in low quality aggregates with limited use cases. Millions and millions of tons of concrete are disposed of in landfills each year. ECR actually breaks the CSH bonds in cement.

Carbon Negative &

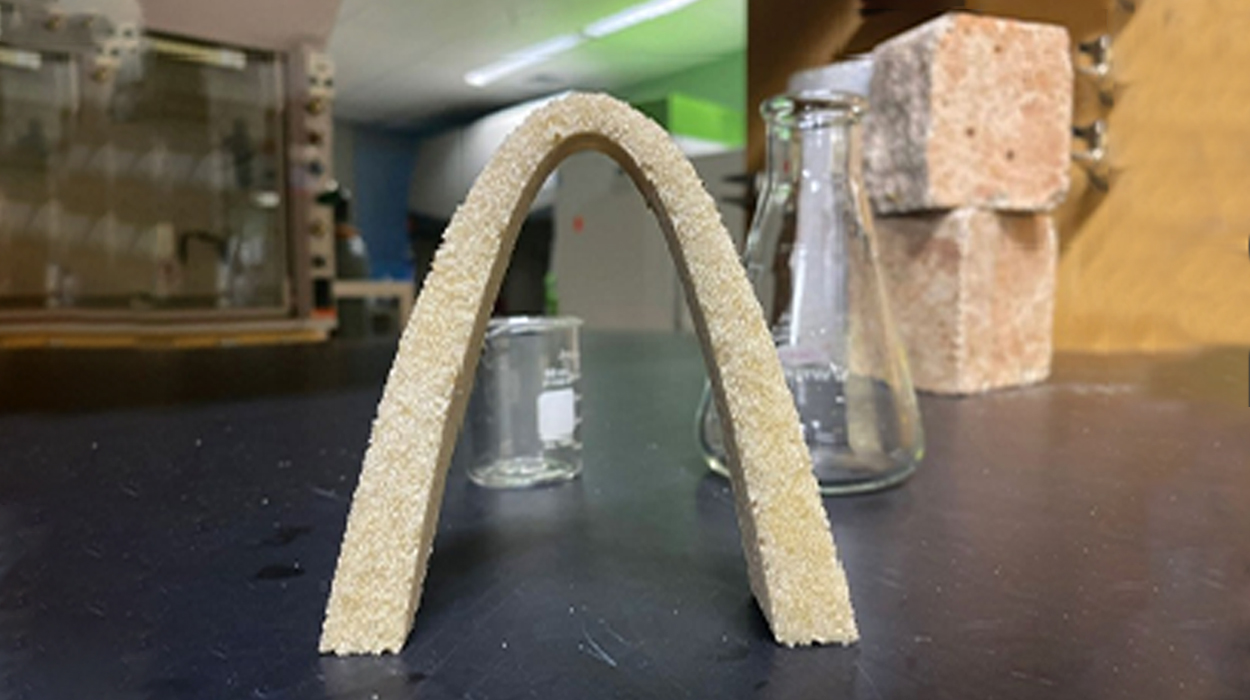

healable ECM

1 cubic yard of Enzymatic Construction Material (ECM) consumes 115 lbs of C02, whereas 1 cubic yard of concrete emits 400lbs of C02! We've most recently achieved an MPA of 30, equivalent to about 4350 psi which means we could potentially use ECM for warehouses, factories, driveways, patios & sidewalks in addition to concrete roof tiles, stucco and load-bearing concrete blocks.

Our Latest Blog & News

Enzymatic on GCCA shortlist of start-ups in global innovation challenge to deliver low carbon concrete

A team from the Worcester Polytechnic Institute has made a strong concrete-like material that soaks up carbon dioxide…

State-of-the-art “living” concrete alternative soaks up carbon

A team from the Worcester Polytechnic Institute has made a strong concrete-like material that soaks up carbon dioxide…

Negative-Emission Construction Material Helps Mitigate Climate

Mitigating climate change is one of the biggest challenges facing the world’s population. Now, a team of…

Enzymes power a carbon-sucking alternative to concrete

Forged with the help of enzymes, a new alternative to concrete pulls in carbon dioxide instead of releasing it…

(Matter 2022, DOI: