Enzymatic Corrosion

Inhibitor (ECI)

Enzymatic Corrosion Inhibitor

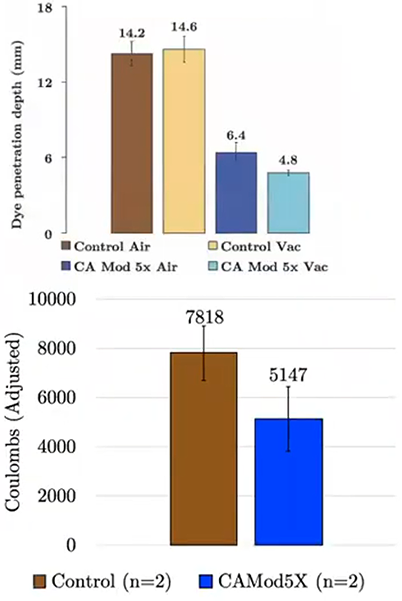

By adding our enzymes to new pours of concrete, we extend the life by at least 4 times with only a 10% increase in cost and do not negatively affect plasticity or cure time. We use an amount of enzyme equivalent to about a drop of water. The only currently approved, state-mandated alternative corrosion inhibitor is Calcium Nitrite (CNI). New York requires 5 gallons of CNI per cubic yard. CNI costs 26% more and is an accelerant so it makes the concrete cure faster and makes it harder to work with. CNI’s also not good for the environment. We have many advantages over the only existing option as we’re less expensive, good for the environment (sequester CO2), have zero negative effects on the concrete and require much less product. Our goal is to make ECI the “Ethanol of Concrete”.

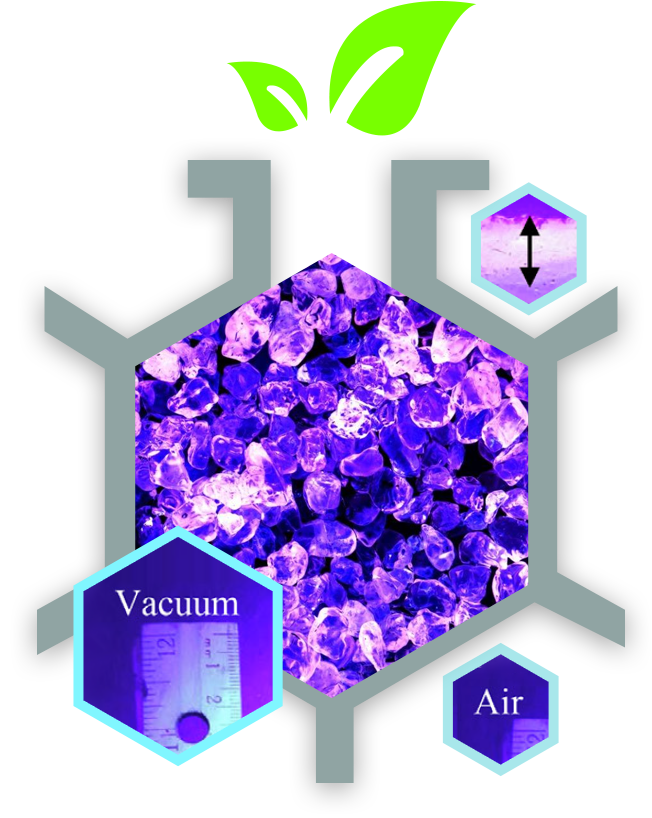

Carbonic Anhydrase for Self-healing

Cement & Carbon Sequestration

Concrete fortified with our Enzymatic Additive will heal itself utilizing direct air captured Carbon Dioxide while

curing which may prevent cracks from forming.

Our Enzymatic Videos

ECI Explainer Video

Enzymatic Corrosion Inhibitor

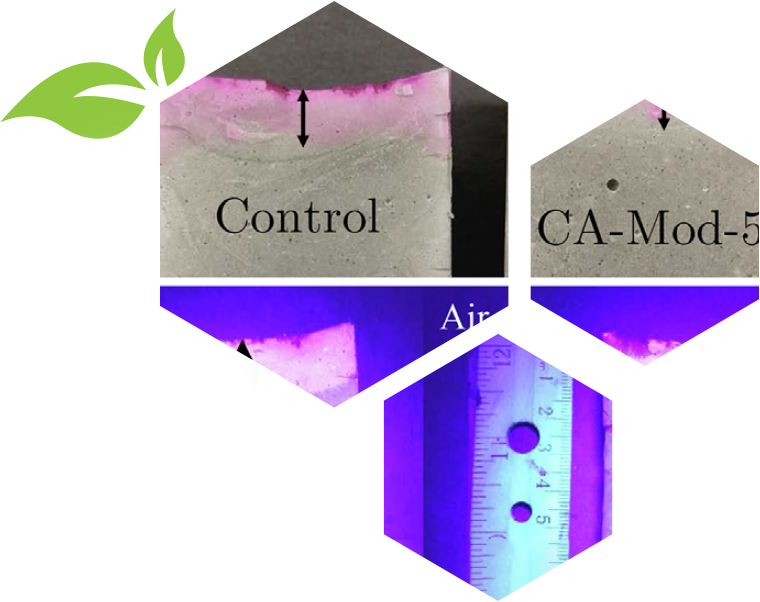

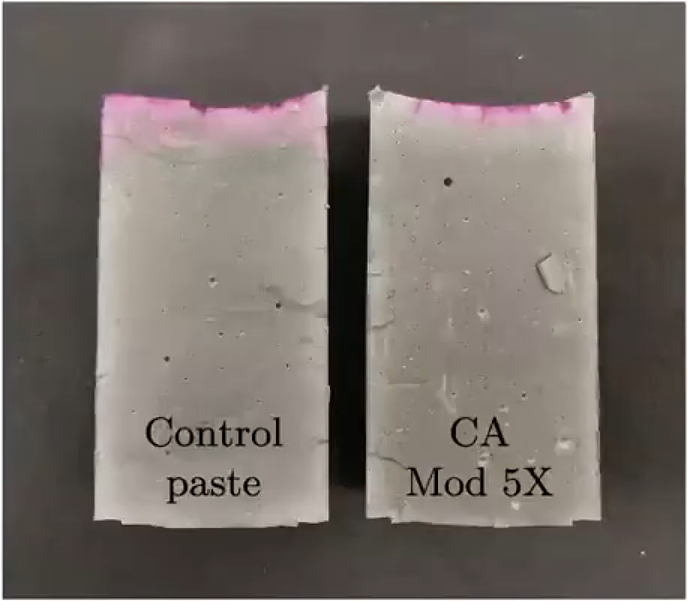

Concrete fortified with our Enzymatic Additive will heal itself utilizing direct air captured Carbon Dioxide while curing which may prevent cracks from forming. The results of multiple Chlorine Penetration Tests and Accelerated Corrosion Tests performed by WPI predict concrete with our Enzymatic Corrosion Inhibitor will last at least 4 times longer, capture carbon and will not negatively affect plasticity or cure time. Concrete will last much longer with only a slight increase (approximately 10%) in cost.